is drop test required for automotive packages|packaging drop testing : vendor Packaging and drop testing protocols, including military standards equipment drop test guidelines, offer comprehensive frameworks to safeguard materials, products, and equipment . webMona Azar (@realmonaazar_) on TikTok | 30 Followers. Entertainer.Watch the latest video from Mona Azar (@realmonaazar_).

{plog:ftitle_list}

Resultado da Classificações da Pro Liga 2023/2024. Flashscore.pt oferece classificações, resultados, comparação entre equipas, estatísticas, comparação de odds da Pro Liga 2023/2024. Além da Pro Liga .

Westpak performs a variety of drop tests including: Package/Parcel Drops. Product Drops. Repeated Impacts. Tumble Testing. Here, we’ll provide a detailed explanation of drop testing along with drop test standards, and share some of .The specimen must drop onto the target so as to suffer maximum damage to the safety features being tested, and: (1) The height of the drop measured from the lowest point of the specimen .

why impact test is required for a material

(a) General. The test procedures prescribed in this subpart are intended to ensure that packages containing hazardous materials can withstand normal conditions of transportation and are .Packaging and drop testing protocols, including military standards equipment drop test guidelines, offer comprehensive frameworks to safeguard materials, products, and equipment .Embarking on a package drop test journey entails meticulous planning and execution. From selecting the apt test standard aligned with package specifications to orchestrating controlled drops using specialized equipment, .

These tests evaluate how a container or packaging can withstand impacts or drops during transportation and handling. Through these tests, companies ensure product durability and reliability while complying with stringent .

winchester copper impact test

Key elements of ASTM D5276-98 include detailed instructions on how to set up the test, the specific equipment required, and the precise process for conducting the drop test.In particular, the ASTM D5276 drop test: Allows manufacturers to assess the structural integrity of a product and/or packaging. Enables manufacturers to evaluate the type of packaging .In the realm of product safety and quality assurance, package drop test models serve as the linchpin. These models, backed by rigorous standards and cutting-edge equipment, ensure that products can withstand the challenges of .The Process of Conducting Effective Drop Testing. Conducting an effective package drop test requires a systematic approach to ensure accurate results. The process involves the following steps: 1. Preparation: Select the .

wwe impact test

As the demand of automotive application grown-up rapidly, electronic packages are required zero defect after manufacturing and ultra-high performance from package level to board-level reliability tests. Since automotive packages operate in dramatic temperature ranges, solder joint combination is recommended chosen high Ag lead-free solder alloy to greatly .

As the demand of automotive application grown-up rapidly, electronic packages are required zero defect after manufacturing and ultra-high performance from package level to board-level reliability tests. Since automotive packages operate in dramatic temperature ranges, solder joint combination is recommended chosen high Ag lead-free solder alloy to greatly enhance the . Board level drop test: This test is intended to evaluate and compare drop performance of WLCSPs for handheld electronic product applications in an accelerated test environment, where excessive flexure of a circuit board causes product failure. It is particularly applied to the power Mosfet and analog wafer-level chip-scale package. A drop tester, offered by Pacorr, is a vital tool in assessing the durability and impact resistance of packaging material.It operates on a straightforward principle: simulating the conditions under which a product might be dropped during transit. By replicating these scenarios, a manufacturer can evaluate the protective qualities of their packaging. The drop test process involves subjecting packages to controlled impacts under specified conditions. These conditions may include drop height, drop orientations, and the number of drops. Key steps .

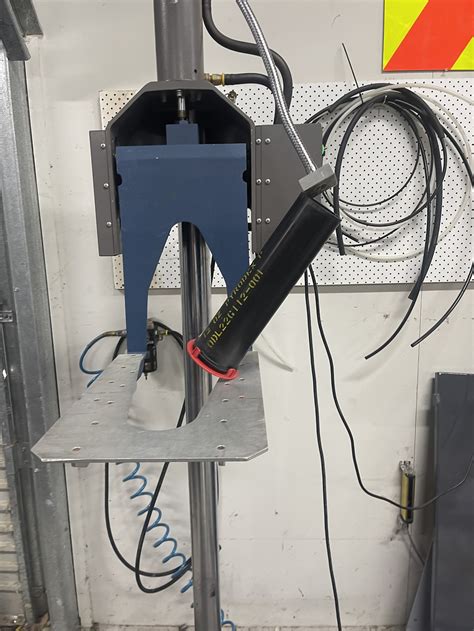

A drop tester is a specialized machine used to evaluate the durability of packaging against impacts, shocks, and drops during handling, shipping, and transportation. By lifting and dropping a test specimen from various heights and angles onto a hard surface, it simulates real-world conditions to observe and assess the impacts on different parts of the package.

Our drop test range is developed for standards-driven testing (eg ASTM D5276) with adjustable drop heights from 1" (25.4 mm) to 96" (c. 2,450 mm). What is the purpose of drop testing? Drop testing mimics the shipping and distribution environment in a way that exposes packages to the types of impacts they may endure while traveling through the .

For other than flat drops, the center of gravity of the test packaging must be vertically over the point of impact. Where more than one orientation is possible for a given drop test, the orientation most likely to result in failure of the packaging must be used. The number of drops required and the packages' orientations are as follows:BGA components used in high reliability automotive microprocessor applications have historically been 0.8mm pitch or larger. Recently, emerging market requirements have pushed BGA pitches down to 0.65mm. However, industry expectations of solder-joint reliability remain constant; customers expect cyclical thermal fatigue lifetimes to be the same as, or in some cases more .

westpak drop testing

product drop testing

Conducting the Drop Test: A drop testing machine or a free-fall method is used to ensure precise and repeatable drops. The method of dropping (manual or mechanical) should align with the standard being followed. Inspection and Evaluation: After the drop test, the package and product are inspected for any signs of damage. The criteria for .Required 5 Vibration TEST BLOCKS 2 & 8 Random Vibration Under Low Pressure Truck or Truck & Air dependent Optional 6 Shock TEST BLOCK 9 Drop 8 Drops - height varies with packaged-product weight. Includes drop on hazard Required 7 Shock TEST BLOCK 10 Rotational Edge Drop 200 mm (8 in) Required for FLAT and ELONGATED 8 Shock TEST .

The Drop Test procedure allow you to comply with the ISTA, ASTM and EN standards. . Package drop tests also allow for the product to be evaluated and for compliance with laws, as well as with industry or specific company standards. . The ISTA-6-AMAZON.COM procedures, required by Amazon for most sellers that use Amazon’s distribution .

packing group ii drop test

Instron is a well-known leader in advanced material and component testing techniques. They supply instrumentation, support services and expertise for testing materials, products and structures. [2] Test engineers needed to develop an impact test machine for automotive bumper testing. The bumper was required to absorb approximately 3,000 While all glass packages passed 1000 thermal cycles at -40/125 °C as predicted by thermomechanical modeling using the Engelmaier-Wild model, the fatigue life of high-CTE samples exceeded 5000 thermal cycles. In addition, 28/30 drop-test samples passed the required 40 and 200 drops on corner and inner circuits, respectively, with no clear .Key elements of ASTM D5276-98 include detailed instructions on how to set up the test, the specific equipment required, and the precise process for conducting the drop test. By adhering to these standardized procedures, organizations .

The automotive industry relies heavily on drop testing to evaluate the durability of various parts, including electronic modules, batteries, and interior components. Drop testers help simulate the stresses and impacts that these parts may encounter during the life cycle of a vehicle, from assembly line handling to road conditions.

For lighter packages, an inspector can do the test themself, probably at your supplier’s factory, however for larger, heavier packages (for instance, 50kg) the test could be done by several people at the same time, or in a testing lab’s facility using a . The density and modulus of elasticity of the solder ball material were identified as the independent factors while the stresses experienced by the BGA package during the drop test is the dependent .

ASTM D5276 is strictly a test method; one cannot use this test method without combining it with a given set of requirements. The test by itself does not have any drop height requirements. This test method, therefore, has to be combined with other technical documents such as an ISTA testing standard. These technical documents will dictate test . It's particularly beneficial in industries where packaging requirements are stringent and package contents need to be in accordance with industry standards and certifications, such as pharmaceuticals, electronics, and food products. How to Choose the Right Packaging Testing Method. Choosing the right method for package testing is vital.Package Drop Test-Buying a drop test machine is a key investment for companies willing to guarantee the safety of their goods during shipping and handling.But if you still have doubts about the effectivity of drop testing or if you want to know if your company needs to run drop tests on your packaged products, in this article we analyze the uses and benefits of the drop testing .

Your inspection company might be able to customize packaging drop test standards with any of your own requirements as well. Package drop test procedure. If you’re shipping an order with only one SKU, you typically only need to conduct a package drop test on a single, full master carton. This is because packaging methods and materials will .

Testing large packages is expensive and is often limited by the availability of test facilities. One popular alternative is to test reduced-scale models. This paper examines the feasibility and difficulties of using scale models for the required drop tests. By analyzing the factors governing the impact responses and failure modes, the paper . This paper deals with the mechanics and physics of board-level drop test with the intention of providing the fundamental understanding required to design and analyse the results of a drop test. By incorporating drop testing into their quality assurance processes, manufacturers can ensure that their products reach consumers in perfect condition, leading to higher customer satisfaction and brand loyalty. Drop Testing Best Practice for E-Commerce In the e-commerce industry, ensuring that products arrive in perfect condition is essential .

Numerous high-quality semiconductor packages have been widely used in these fields due to the recent advancements in the automotive electronics, communication, computer, aerospace, and artificial intelligence industries [1, 2].The recent advance of electronic science and technology has pushed the updating of electronic products which are expected to have high .

wwe impact testing online testing

wwe.impact testing online/testing

WEBPara um bolo do Palmeiras, verde e branco. Da mesma forma, é interessante usar tudo que é relativo à equipe: jogadores famosos, escudo, mascote, títulos, entre outras .

is drop test required for automotive packages|packaging drop testing